Prototype Business

Tianma Japan offers high reliability and quality products that utilizes own LCD manufacturing capability/know-hows, provides various type of film deposition, patterning and glass cutting, and can be a partner who can cooperate in the development of new technologies and new products in material, processing, machine manufacturers and research institutes.

Feature of prototype

| • Integrated process (deposition, patterning, cutting) |

| • Various metal materials, inorganic insulating film materials, and organic insulating film materials are available |

| • Support small-quantity level trial production to mass production. |

| • Support design such as CAD works. |

| • Support the production of products not only LCD and the contract processing of prototypes using LCD manufacturing technology, equipment, and know-how. |

| • Thick Cu wiring processing with Cu plating is available. |

| • Measurement such as thickness of layer for samples is an option. Please let us know. |

| • Mounting IC, assembling FPC to glass are an option. Please let us know. |

| • Reliability test is an option. Please let us know. |

|

Available process

■Substrate processing *Process based on 550x660mm and thickness of glass:0.5mm or 0.7mm.

|

Process |

Equipment |

Remarks |

|

|

Cleaning |

UV/Chemical/Highpressure/Ultrasonic/Pure water |

|

|

|

Deposition |

Metal |

Sputter |

AlNd, MoNb, ITO, Cr, Cu,Ti etc |

|

Insulator (inorganic) |

P-CVD * |

SiNx, SiOx, etc. |

|

|

Insulator (organic) |

Spin coater |

Acrylic resin, Polyimide resin |

|

|

Semiconductor |

P-CVD, Sputter |

a-Si, InGaZnO₄ |

|

|

Patterning Photolithography |

Coating resist |

Spin coater |

|

|

Exposure

*Tianma Japan can support design |

Aligner |

Processing ability≥4μm |

|

|

Stepper |

Processing ability≥4μm |

||

|

Development |

Development |

Developer solution: TMAH 2.38% or 0.4% |

|

|

Etching |

Dry etching |

SiOx, SiNx, Cr |

|

|

Wet etching |

AlNd, MoNb, ITO, Cu, Ag |

||

|

Stripping |

Amine based treatment |

||

|

High temperature annealing(bake) |

Hot air circulation |

O2 concentration can be adjusted by N2 |

|

*Please refer to the following table for the thickness of each material.

*Pegarding P-CVD, film formation is possible even on small sized substrates and silicon wafers.

| CVD equipment slot | CVD equipment | ITO sputter |

|

|

|

| Photolithography equipment slot | Stepper | Dry etching equipment |

|

|

|

Table1:Deposition material, Thickness, Line width, Resistance

Below is available type of material, thickness.

|

|

Type |

Thickness |

Minimum line width / Spacing(μm) |

Ratio value |

Remark |

|

Wiring/ |

AL alloy |

30~500 |

4/5 |

5 |

With Mo Alloy lamination |

|

Mo alloy |

30~300 |

4/4.5 |

16 |

||

|

ITO (Transparent conductive) |

40~200 |

4/5 |

165~800 |

||

|

Cr |

30~50 |

4/4 |

20 |

||

|

Cu |

30~200 |

4/9 |

2 |

||

|

Ti |

25~100 |

- |

80 |

Ti layer patterning is not available. |

Thickness, line width and spacing is just guideline.

Measurement such as thickness of layer for samples is an option. Please let us know.

Table2:Material, Thickness, Line width

|

|

Type |

Thickness |

Minimum line width / Spacing(μm) |

Remark |

|

Insulator |

SiNx |

50~1000 |

5 |

Contact hole formation available |

|

SiOx |

50~200 |

5 |

||

|

Acrylic resin |

800~30000 |

10 |

||

|

Polyimide resin |

550~3000 |

10 |

||

|

a-Si |

10~250 |

5 |

|

|

|

InGaZnO₄ |

30~200 |

5 |

Thickness, line width and spacing is just guideline. If you have request, please let us know.

Measurement such as thickness of layer for samples is an option. Please let us know.

■Post-process

|

Available contents |

Equipment |

Remark |

|

Sealing |

Dispensing |

Seal width:0.5~2mm level |

|

ODF |

ODF equipment |

Alignment level:±6μm |

|

Thermosetting Seal material |

Hot air circulation |

|

|

Slimming |

Chemical etching(outsource) |

Up to 0.2t on one side |

|

Cutting |

Regular cutting machine Free form cutting machine |

tolerance:±0.3mm Please ask the cutting size and free form shape. |

|

Polishing edge |

Polishing machine | Size:100mm□~550mm□ |

|

Cleaning |

Pure water cleaning |

*Orientation processing (alignment film printing, rubbing (photoalignment), etc is not available.

■Bonding

|

Available contents |

Equipment |

Remark |

|

Bonding |

Film bonding device machine |

Available size (middle size) Available size (large size) |

|

Sensor & Touch panel bonding |

Includes vacuum bonding UV curing treatment by OCR |

Available size 87x142~325x490mm |

|

OCA bonding |

||

| Touch panel bonding to LCD module |

Includes vacuum bonding UV curing treatment by OCR |

|

|

OCA bonding |

||

|

Adhesive bonding |

| Film bonding device machine | Vacuum bonding equipment |

|

|

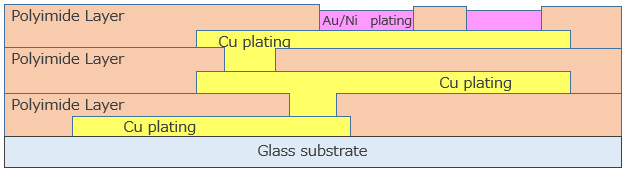

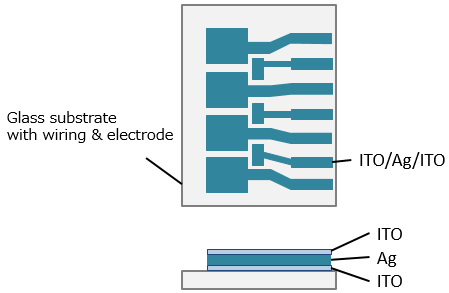

■Plated wiring board processing

The following plated wiring processing is available.

*Processing based on 550x660mm 0.5/0.7t glass substrates is available.

|

Film type |

Available film thickness and line width [μm] |

Remark |

|

Cu plating thickness |

2~12 |

Formed on seed Cu/Ti |

|

Polyimide layer thickness |

6~15 |

|

|

Cu plating: Minimum line width/spacing |

5/5 |

Varies depending on Cu film thickness |

|

Contact Hole Diameter |

>10 |

Varies depending on polyimide film thickness |

|

Au/Ni plating thickness |

standard 0.05/3 |

|

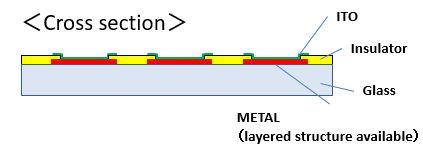

Cross section |

|

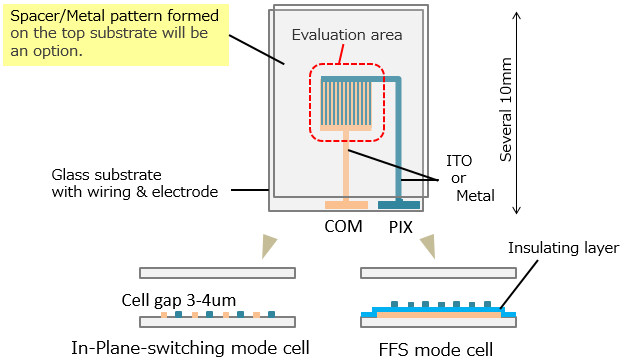

Case of product 1: LCD materials evaluation

|

Tianma Japan offers the substrate for evaluation of Liquid Cristal , Polyimide materials.

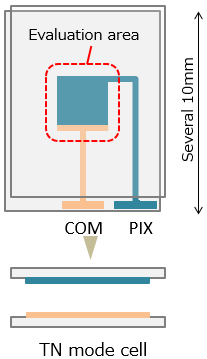

Case of product 2: OLED materials evaluation

Offering the substrate for OLED materials. |

Tianma Japan Sample image |

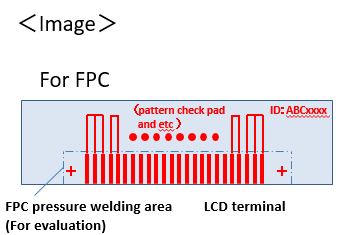

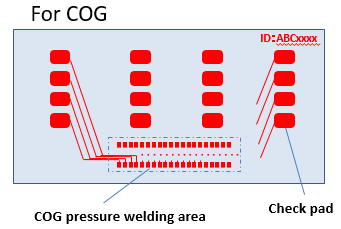

Case of product 3: ACF material evaluation

|

|

Tianma Japan supports test samples for evaluation ACF materials.